We are the Jute Products Supplier. We have a very good collection of products including unique design and expert resources to ensure product quality, delivery timing, affordable pricing, etc. We hope we can align with your requirements & can do a long-term business with the betterment of the environment for the next generation. Jute bags are Made in Bangladesh. It's natural, Eco-friendly, and easy to dispose.

.jpg)

Jute has an overall positive impact on the environment. In fact, it is one of the few natural fibers that actually provides environmental benefits instead of being detrimental. Both rice and jute are generally grown in the same areas since these crops require similar growing environments. While rice depletes the soil in which it is grown, jute production actually returns nutrients to the soil and helps retain soil moisture. Therefore, rice and jute are symbiotic crops, and growing these two agricultural products together diminishes the environmental impact of rice cultivation. As with all types of fiber crop cultivation, however, there is both a right and a wrong way to cultivate jute. If jute is not grown sustainably by following basic practices like crop rotation, this crop could hurt the surrounding soil. While jute production generally does not necessitate the use of chemical fertilizers and pesticides, if cultivators of this crop use these toxic chemicals in their production processes, jute’s environmental impact can rapidly become negative.

Reusable

Environmentally friendly.

Do not require maintenance.

100% bio-degradable and recyclable

Cost-effective and cheaper than plastic and paper bags.

Strong and can carry more weight as compared to promotional carry bags.

Durable and long-lasting, not easy to tear like plastic and paper bags do.

Jute has good insulating and antistatic properties, low thermal conductivity, and moderate moisture retention.

Jute bags look smart, trendy, and stylish.

Jute is used in a wide variety of goods. Jute mats and prayer rugs are common in the East, as are jute-backed carpets worldwide. Jute’s single largest use is in sacks and bags, those of finer quality being called burlap or hessian. Burlap bags are used to ship and store grain, fruits and vegetables, flour, sugar, animal feeds and more1.

Jute is also used to make cloth for wrapping bales of raw cotton and to make sacks and coarse cloth. The fibers are also woven into curtains, chair coverings, carpets, area rugs, hessian cloth and backing for linoleum. Jute, known as the “Golden fiber” 100% biodegradable and eco-friendly material and pollution free for environments, and we should promote the usage of jute products so that we can also contribute to our environment to make our planet plastic free, clean and healthy place.

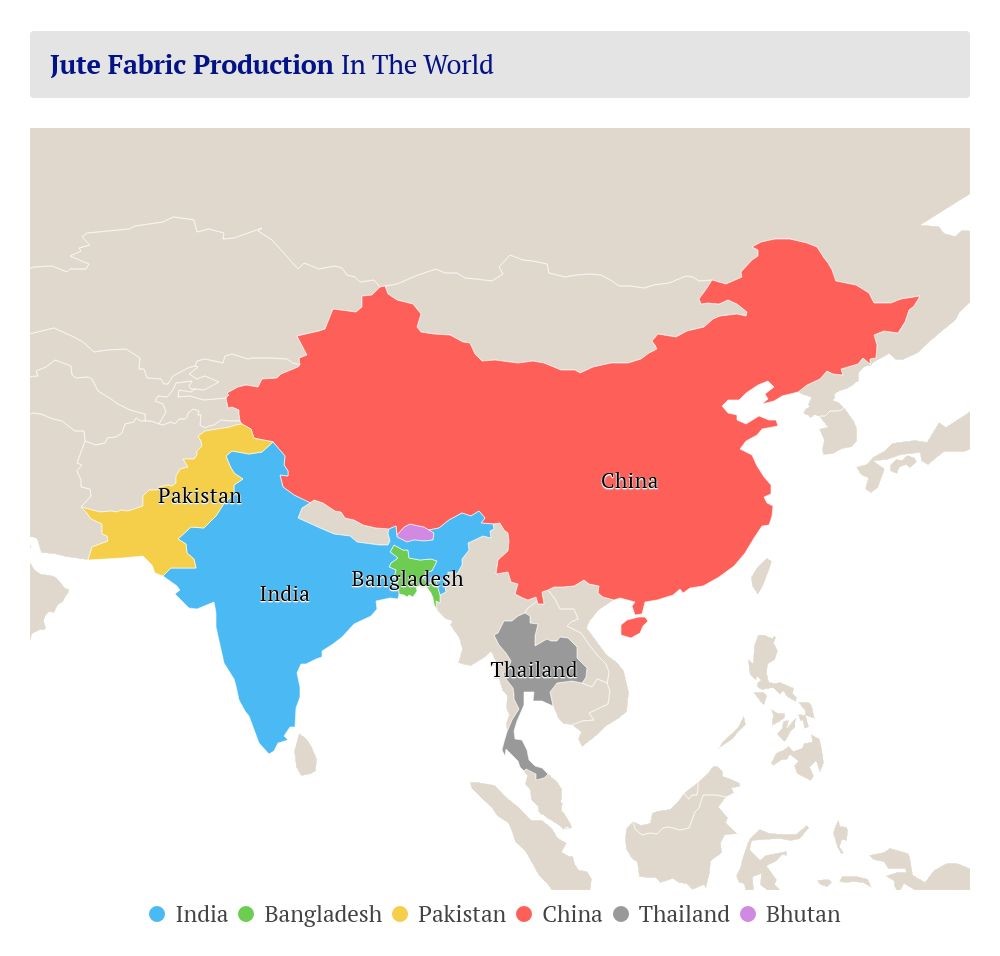

Jute fabric is a type of textile fiber made from the jute plant. While there are a few different botanical varieties of jute, one of the main species used to make jute fabric is Corchorus olitorius (white jute). However, another species of jute, called Corchorus capsularis (tossa jute) is considered to be superior even though it is harder to cultivate. Cotton takes the title of most-produced plant-based fiber, but jute is a close second. While jute isn’t very popular in the Western world, it is one of the primary textile fibers of India and neighboring countries. Jute plants grow to be over 10 feet high, and the fibers derived from these plants are harvested in a single long string. Therefore, jute fibers are among the longest natural textile fibers in the world. Jute grows in similar conditions to rice, and this plant is best suited to warm areas that have annual monsoon seasons. This crop cannot grow in hard water, and ambient humidity level of approximately 80% are necessary for jute production.

Jute has been grown for textile purposes on the Indian subcontinent for at least 5,000 years. The earliest evidence for the production of this plant fiber dates to approximately 3000 BC, but it’s entirely possible that the Indus valley civilization or preceding societies also cultivated jute for fiber purposes before this date. Even though cotton production was also popular in India, jute played a more central role in the development of Indian society for the millennia preceding the effects of European colonialism. With the advent of British involvement in India, jute became a cash crop that helped fuel British colonial efforts While jute had also been grown in Scotland for several centuries, jute production in Bengal and other parts of India quickly overtook Scottish production. Due to the immense profits being made by jute barons in India, many Scottish jute producers emigrated to this British colony to partake in the jute boom. Jute production remained a significant sector of the economy of the British Empire until the late 19th century, and after Indian independence, jute remained a major export of this region. With the advent of synthetic fibers, however, jute production slackened in the latter half of the 20th century, and it wasn’t until the early 21st century that production of this plant fiber again became a major economic factor in Bengal, Bangladesh, and other areas of the Indian subcontinent.

Jute is a relatively rough fiber, which means that it isn’t well-suited for apparel applications unless it goes through an extensive production process. Instead, jute’s roughness and durability make it ideal for industrial applications. Most types of jute fabric are loose with woven networks of thick yarn. While jute absorbs water readily, it also dries quickly, and it is highly resistant to abrasion and stains. Being plant-based, however, jute biodegrades relatively quickly, and it isn’t known for its long-term durability in outdoor applications. Most types of jute fiber are light brown, but some off-white varieties also exist. Generally speaking, white forms of jute are considered to be inferior to brown forms, but white jute may be more useful for apparel applications. Since it is thick and pliable, jute fiber is generally easy to work with, and since this fiber is long and shiny in its unprocessed state, manufacturing jute yarn is relatively easy. Jute is highly breathable, but it doesn’t naturally retain much heat, which makes it an ideal apparel material for hot and humid climates.

The production of jute fabric has remained largely the same for centuries. In most cases, mature jute stalks are harvested by hand, and they are then defoliated. Jute fibers can be derived from both the inner stem and the outer skin of the stalk. A process called retting is used to remove the non-fibrous material from the stem and skin of the jute stalk. Retting softens the stalks and makes it possible to separate the fibrous material from the unusable material by hand. After the jute stalk has been retted, it is possible to separate the long, silky fibers and comb them into long strings. These combed fibers can then be spun into yarn. While it’s technically possible to make jute yarn with automated machines, most jute-producing communities still rely on analog spinning wheels for this process. Once jute fiber has been spun into yarn, it may be subjected to a variety of chemical processes to dye it, provide it with water resistance, or make it fire-resistant. Then, the finished reels of jute fiber are shipped out to textile production facilities to be woven into apparel or industrial textiles. In the case of jute apparel, a variety of softening techniques are used to make the finished apparel products more comfortable. Some manufacturers may agitate the jute yarn to reduce its roughness, or chemical techniques may be used to achieve the same effect. Jute fiber used for industrial purposes can generally be left in its original condition without using any softening techniques.

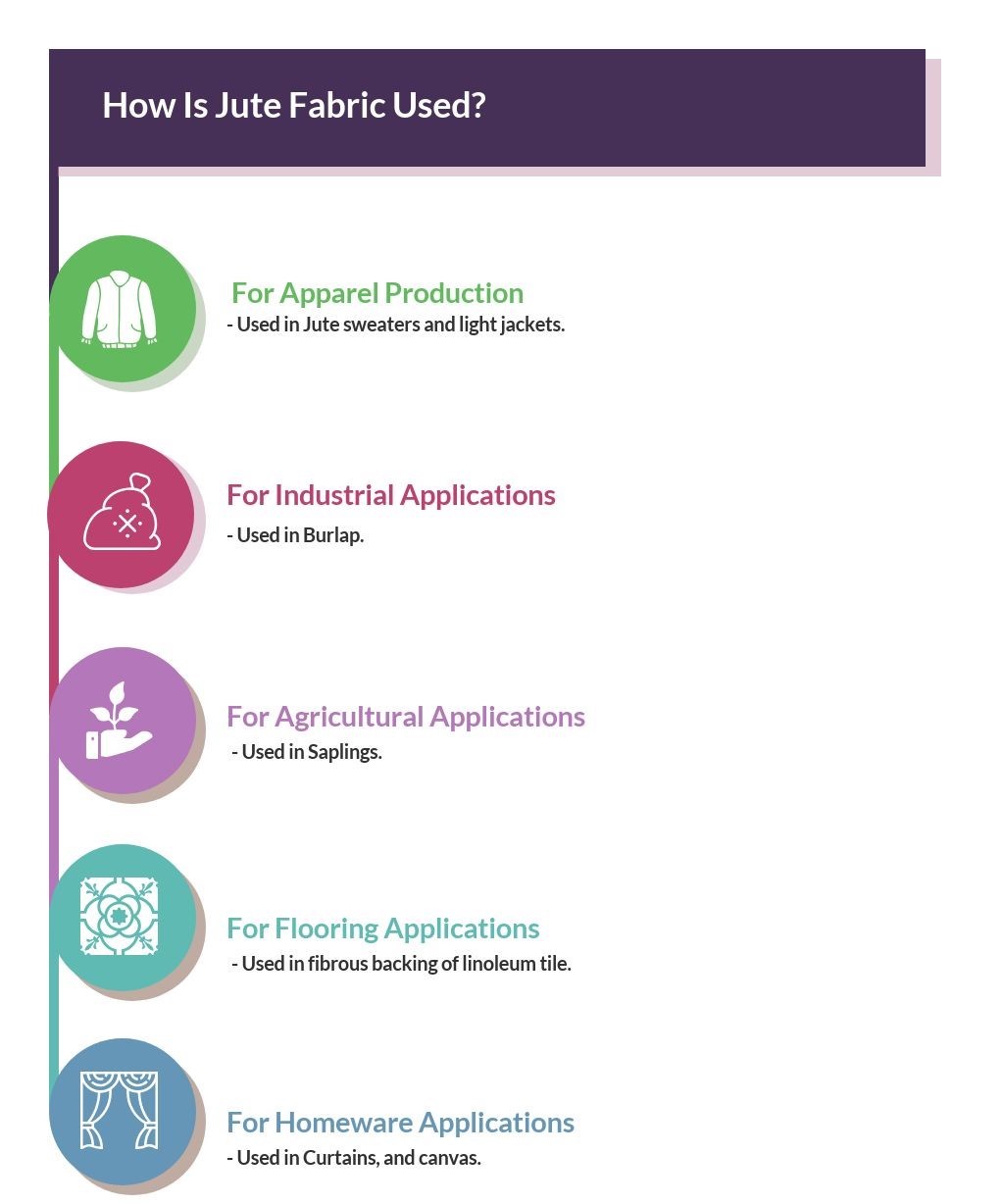

Due to its rough texture, jute is not commonly used for apparel production. Recent advancements in jute processing, however, have made it possible to use this traditionally uncomfortable textile for certain types of garments. While it’s still uncommon to find jute used in undergarments or apparel that makes direct contact with the skin, jute sweaters and light jackets are rapidly gaining popularity worldwide. The traditional uses of jute, however, remain the most popular applications of this fiber. For instance, jute is synonymous with burlap, which has been used for centuries as an industrial material in the Western world. Burlap sacks have long been used to transport vegetables, fruits, and other goods, and burlap has also been used as an insulative material. Jute also continues to be used in agricultural applications. It’s common for jute fabric to return to its point of origin as a protective measure against erosion in jute and rice fields. This fabric is also used to make the protective wrappings around sapling roots when these juvenile trees are transplanted. Since jute is readily biodegradable, saplings can push their roots right through jute fabric bags without encountering any significant resistance. Basic fibers made from jute are used in a variety of flooring applications. The fibrous backing of linoleum tile is generally made from jute, and this fiber may also be used to make rugs, carpeting, or other types of fibrous flooring. Due to its roughness and durability, jute is popular in general homeware applications. For instance, this fabric is popular for upholstery (especially for outdoor furniture), and it is also used to make curtains and canvas. Intriguingly, jute is a major constituent of ghillie suits, which are advanced forms of camouflage that allow military combatants to blend into grassy or otherwise foliage-rich environments.

Jute fabric is one of the world’s least expensive textiles. While artisan forms of jute may be more expensive, most types of this fabric cost around $1 per yard. This price is comparable to cotton, and it is significantly less expensive than many types of synthetic fabrics.

The most inexpensive way to purchase jute fabric is to work directly with a manufacturer in India, Bangladesh, or another jute-producing country. Taking this approach stimulates the local economy, and it empowers textile producers to overcome exploitative crop production paradigms.

While there are two main varieties of jute, these forms of this prominent textile fabric aren’t the only types of jute in existence:

1. White Jute

White jute isn’t anywhere near as popular as it once was, but historical records suggest that this fabric used to be the main textile used to clothe the common people of the Bengal region of India. As its name suggests, white jute is lighter in color than other strains of this fiber, but this type of jute is also less durable than its cousins.

2. Tossa Jute

Tossa jute is the main type of jute in production today. It is a hardy crop, and it yields more fiber than white jute. In color, tossa jute is more brown than off-white, and its fibers are just as long and strong as any other type of jute in existence.

3. Mesta Jute

Mesta jute is a hybrid of white jute and tossa jute. While this type of jute wasn’t popular historically, political complications during India’s tumultuous independence period led to the prominence of this type of jute’s production

4. Jute Cuttings

Jute cuttings are byproducts of jute production. They are the roughest and least desirable parts of the jute plant, but they can still be used to make rudimentary textiles.